ALMA Band 2 LNA

145 LNAs for ALMA Band 2.

As part of the Wideband Sensitivity Upgrade (WSU) of the ALMA observatory, the division was awarded a production contract by the European Southern Observatory (ESO) for the first-stage low-noise amplifier (LNA) used in the new Band 2 receivers. These receivers span the 67–116 GHz frequency range, covering and replacing the existing ALMA Band 3. Receiver production is currently underway, with the first units already undergoing integration and testing at the observatory. The contract award follows the successful delivery and evaluation of prototype devices, which demonstrated performance meeting ALMA’s stringent specifications. As of May 2025, 90 out of 145 LNAs have been successfully qualified and delivered to ESO. The production and qualification process is ongoing and progressing as scheduled. This achievement is the result of several years of joint development between the Max-Planck-Institute for Radio Astronomy (MPIfR) and the Fraunhofer Institute for Applied Solid-State Physics (IAF). Our long-standing collaboration focuses on the design and fabrication of cryogenic monolithic microwave integrated circuit (MMIC) LNAs with state-of-the-art noise performance.

Part of the development was carried out within the framework of European Union research programs such as AETHRA, which supported critical aspects of amplifier optimization and fabrication process refinement. To support production-level testing, a dedicated cryogenic W-band test facility was developed and commissioned by the division. This system enables precise and repeatable performance verification of each LNA unit under cryogenic conditions, in line with the demanding qualification criteria defined by ESO.

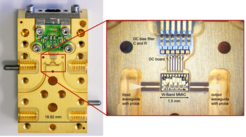

Fig. 1 depicts the open waveguide split block housing and shows the internal components of the lower half with the right image showing a zoomed in view of the central area. Based on their superior demonstrated noise performance, our LNAs were designated as first-stage amplification. The housings are milled in MPIfR’s own precision machining workshop in which critical components such as waveguide features can be milled with consistent accuracy in the micrometer range. During start-up of production, it was possible to utilize the newly acquired 5-axis CNC that simplifies the complicated milling process (Fig. 2, left). Similarly, the housings are gold plated at MPIfR’s electroplating workshop with cryogenically proven processes. Trials with industry partners had demonstrated inferior results to those of our inhouse workshop. This underlines the importance of dedicated MPIfR facilities for instrumentation development.

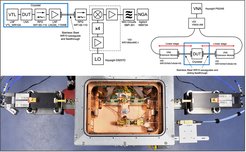

Adhering to the highest standards, the LNAs need to be qualified against an extensive specification sheet from ESO, with all performance critical testing performed at Tamb = 15 K. Cryogenic testing is resource intensive due to the durations required for cool-down and warm-up and needs to be carefully planned for in a production process. A dedicated qualification test setup was developed that incorporates two test channels under software automation (Fig. 3). Data analysis is performed using a pipeline that qualifies all required test parameters for their compliance and generates the test reports. This tool set can also be instrumental in tracking hundreds of components for even larger scale projects in the future. Furthermore, the test setup features a novel approach for measuring the required phase and amplitude stabilities of the LNA utilizing a single vector network analyzer-based measurement (to be published).

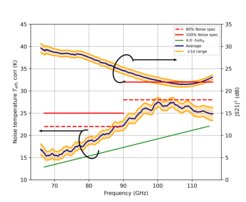

Fig. 3 summarizes the test results for noise temperature Teff (K) and gain (dB), two crucial figures of merit for LNA performance, for the ongoing production of the qualified LNA. This project is expected to generate an extensive homogeneous data set for these high-performance LNAs that will improve our general understanding on cryogenic transistor models developed at Fraunhofer IAF.