Vacuum Technique and Refrigerator Technology

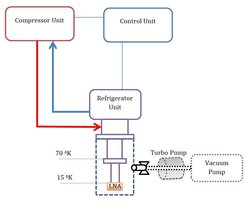

In our Radio Astronomy Receiver system, we are using the Gifford-McMahon refrigerator system for cryogenic cooling down to 15 K temperature range. Standard industrial-type 2-stage (15 oK and 70 oK) Gifford-McMahon (GM) refrigerators were selected to serve as reliable cooling devices, known to implement proven technology, low vibrations, orientation-free operation, adjustable frequency and practicable mean-time-between-failure (MTBF) respectively service intervals. The main components of the systems are Compressor Unit, Control unit, Refrigerator Unit and a separate Vacuum pump unit.

Duty of the system group is monitoring and maintenance of the cooling system; maintenance of compressors, refurbishment of refrigerators, R&D on control units and keeping helium pressure constant. Our staff is trained to maintain compressors of the type Somitomo F11 and CTI, mainly by changing absorbers and adjusting pressures. Main duty is the refurbishment of refrigerator units type CTI 350 and equivalent units. There are about 20 units of this type in operation each needing maintenance every two years in average.

Cryo cooled receiver systems

To get rid of the thermal noise component of the most sensitive components in the receivers the input circuit including the first low noise amplifier (LNA) is cryogenically cooled to 15 K. Depending on frequency we try to cool the whole circuit in front of the LNA in a vacuum container (Dewar): feed horn and Ortho mode transducer. At long wavelengths, cooling of the feed horn is not feasible as the volume of the Dewar would be too big. For more information on our receiver systems read systemgroup_receiversystems and the pages of the departments receiver group, where these units are designed and manufactured.

Click here to read an article on advanced high-cooling power 2-stage Gifford-McMahon refrigerator systems.