Cryogenic Phased Array Feed (Cryo-PAF)

The Cryogenic Phased Array Feed (CryoPAF) project deals with the realization of novel multi-element radio astronomical receivers for the 100 m Effelsberg radio telescope. The project is embedded into the collaboration on “Low Frequency Gravitational Wave Astronomy and Gravitational Physics in Space” between Chinese Academy of Science (CAS) and Max Planck Gesellschaft (MPG).

In contrast to conventional single-pixel feed receivers located at the focus of a parabolic dish antenna, a CryoPAF system provides cost effective multi-pixel receivers. The novel receiving system with up to several hundred receiving channels consist of various parts including receiving elements that collect the energy from deep sky, low noise amplifiers (LNAs) and filters in order to produce a signal. By properly weighting the corresponding signal from each receiving channel, multiple beams can be formed that look in different directions in the sky, hence providing a wide field-of-view (FOV).

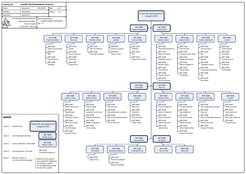

The development of the Cryo-PAF project has six work packages (WP); namely, Project Management, Design studies, Final Design, Build up, Commissioning and Operations. The first WP relates to the organization, structure and control of the project during all phases. All other WPs reflect the development stages of the receiver system and are divided into four main receiver system components; i.e. Receiver system, Cryostat (see below), Frontend signal path and Backend system (see below).

Cryostat

A cryogenic PAF system for Effelsberg might require, depending on its frequency of operation, hundreds of cryogenic LNAs. The technology group and Fraunhofer IAF (Institute for Applied Solid State Physics) maintain a close and long-standing cooperation for the design and development of cryogenic LNA MMIC’s. Within this cooperation, a prober station was developed at the MPIfR to perform large volume semi-automated measurements of noise and S-parameters at cryogenic temperatures. The system is capable of on-wafer characterization of several 100 MMICs during a single cooling cycle at a temperature of ~12K.

A process was developed identifying MMICs of suitable cryogenic performance on-wafer in a single cooling cycle instead of tedious packaging & cryogenic testing of hundreds of individual connectorized modules. This procedure is thus a prerequisite only enabling the construction of larger cryogenic PAF’s. Within the MeerKAT project, requiring the fabrication of ~160 LNAs, this approach was tested very successfully for the first time.

For the Cryo-PAF project, the group is also involved in the development of planar assembly techniques that fulfill the need for focal-plane modules with high density of integration, i.e. COB (Chip On Board). For such an approach availability of known-good LNA MMICs at cryo-temperature is even more important, since reworking a high-density module to replace bad MMICs might turn out being risky or even impossible, which then would inevitably lead to dead pixels.

In addition, a cryogenic PAF might take large advantage from the use of superconducting circuitry, thus it is planned to upgrade the cryogenic prober to allow for testing of superconducting circuits made from NbN or even Nb films, which would require the prober to reach a base temperature of ~6K.

Backend system

The backend development group is in charge of the design and prototyping of the backend signal processing subsystem of the CryoPAF. The backend subsystem is responsible for handling the digitised, packetised voltages output by the CryoPAF's first-stage channelisers, first distributing the data to the appropriate compute resources before performing the necessary operations required to deliver science ready data, e.g. beamforming, correlation, channelisation, polarimetric detection, pulsar folding, etc. The large volume of data produced by the CryoPAF frontend, presents us with many challenges in designing a backend with such a wide array of functionality. As such, the design work undertaken by the group also includes prototyping and de-risking of the latest and greatest accelerator, storage, and transport technologies.